- Material

-

- Aluminium 61

- Brass 8

- Stainless Steel 8

- Galvanised Steel 1

- Mild Steel 1

Is Galvanised Steel Bad for the Environment?

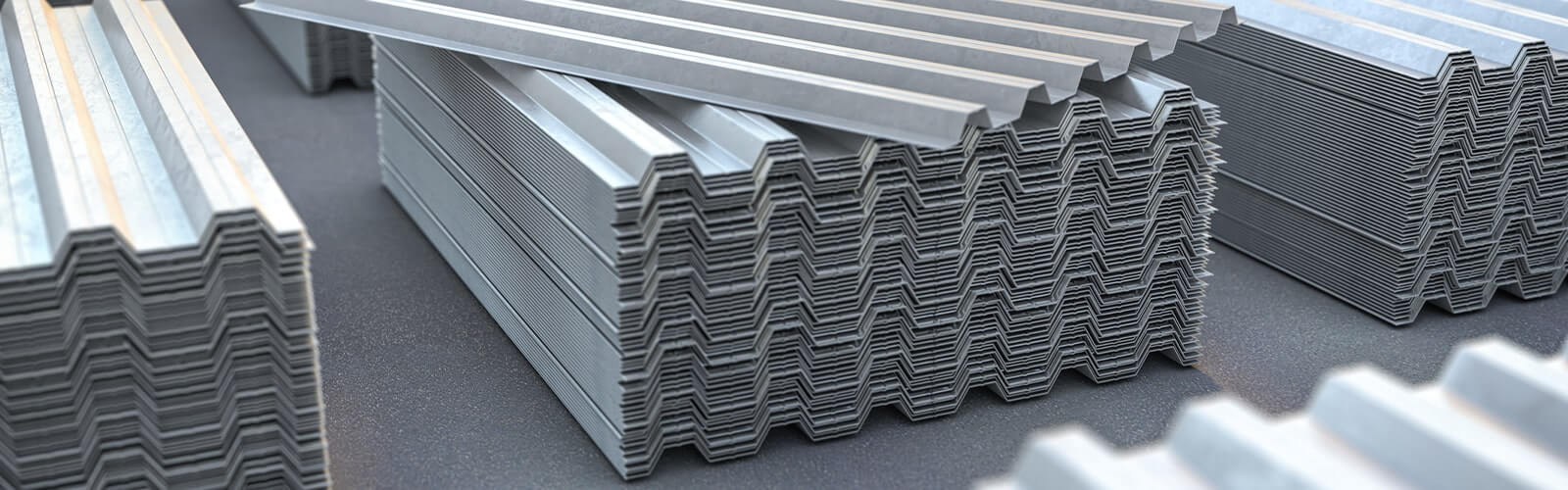

Galvanised steel - steel that's been coated in a protective layer of zinc to prevent rusting - is a popular component in projects of all sizes. More resilient than standard steel but more affordable than stainless steel, it's an excellent midpoint suitable for a variety of structural applications.

With concerns about environmental damage intensifying, however, many people are thinking more about the ecological footprint of the materials they use - and that includes galvanised steel.

As one of the UK's leading metal stockholders, the team at Clickmetal know all there is to know about steel, including stainless, galvanised, and mild steel. Below, we take a look at how sustainable galvanised steel is compared to other materials, and whether it's a good choice for your project.

Is Galvanised Steel an Eco-Friendly Material?

As with many materials, the answer isn't a simple yes or no. Galvanised steel shares many of the same environmental drawbacks of carbon steel, such as resource depletion and high energy consumption during production. However, it also offers several benefits that make it a more eco-friendly option overall, such as:

1. Durability

Galvanised steel's exceptional corrosion resistance extends its lifespan, reducing the need for replacements and the resulting environmental burdens, like new material production and waste generation. This is particularly important for long-lasting infrastructure projects.

2. Energy-Efficient Coating Process

Most galvanised steel is coated using a process called hot-dip galvanising. This involves dipping the metal into molten zinc at a temperature of around 450°C. Compared to other methods of steel coating, hot-dip galvanising is notably energy-efficient: it efficiently utilises heat, often generated by natural gas or electricity in a furnace, to melt the zinc. By retaining much of the generated heat within the furnace, the process reduces energy waste. On top of this, zinc production has a relatively low energy intensity compared to other metals.

3. No Need for Solvents

Because galvanised steel already has a protective coating, it doesn't need to be painted or coated in epoxy to protect it from rust. This cuts down on solvent use and its associated emissions.

4. Recyclability

Galvanised steel retains its protective properties even after multiple uses and can be recycled at the end of its lifespan without compromising its effectiveness. This minimises the demand for new materials and reduces landfill waste by repurposing existing galvanised materials to create new ones.

5. Reduced Waste During Production

When performed correctly, the hot-dip galvanising process produces very little waste. Zinc that doesn't adhere to the steel during coating can be collected and reused, while zinc that flakes or falls off can be returned to the hot baths and melted down again.

Is Galvanised Steel the Right Choice for My Project?

Galvanised steel's strength and affordability make it ideal for a variety of applications, and while it does have its environmental drawbacks, it still stands as a greener alternative to many other building materials. This means it can be combined with other sustainable materials for a more planet-friendly project.

Buy Premium, Custom-Cut Galvanised Steel Sheets

Need components for your next project? As the UK's leading provider of top-quality metals, Clickmetal can deliver precision-cut galvanised steel sheets right to your front door.

Our sheets are made from grade DX51DZ+275MAC galvanised steel, known for its excellent corrosion resistance and non-magnetic properties. They feature a durable zinc coating that provides extended protection in any environment and are available in thicknesses ranging from 0.7 mm to 3 mm to suit your unique project needs.

We understand that timely delivery is key, so once your order is placed, we'll process it within 3-5 days and send it out via next-day courier delivery. Whether you need a few specialised parts or bulk materials, we've got you covered.